We offer state-of-the-art bottling plant machinery that ensures precision, high productivity, and minimal downtime. Our machines are designed for efficiency in handling, filling, and capping bottles in various sizes, making them suitable for a wide range of industries.

Our glass production machinery includes everything needed for manufacturing high-quality glass products. From melting furnaces to shaping and forming equipment, we ensure a smooth production flow and top-notch quality control.

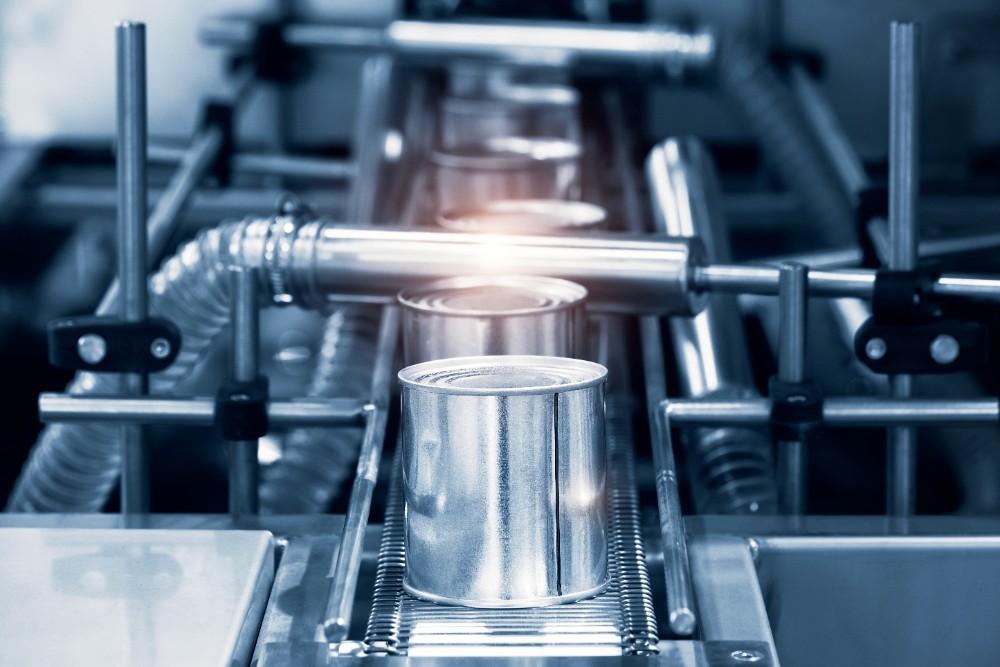

We provide comprehensive canning solutions with advanced machinery for washing, filling, sealing, and labeling cans. Our equipment ensures quick and precise operations, making it ideal for industries in need of large-scale canning production.

Machinery Supply

2000lph water treatment system

1.Raw Water Pump

Material: Pump constructed with high-grade stainless steel (SUS304). Flow Rate: 3 m³/h. Flow Distance: Capable of reaching a flow length of 32 meters.

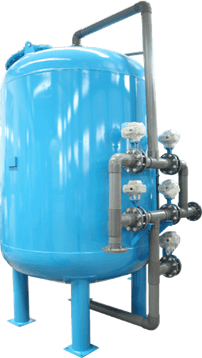

2.Quartz sand filter

Dimensions: Height - 2000 mm; Diameter - 600 mm.

Material: Food-grade stainless steel.

Components: Includes water sender, water collector, pressure gauge, filtration material, valves, and more.

Filter Media: Quartz sand.

Application: Primarily designed for removing algae, suspended solids, colloids, and similar impurities.

Filtration Capacity: 3 m³/h.

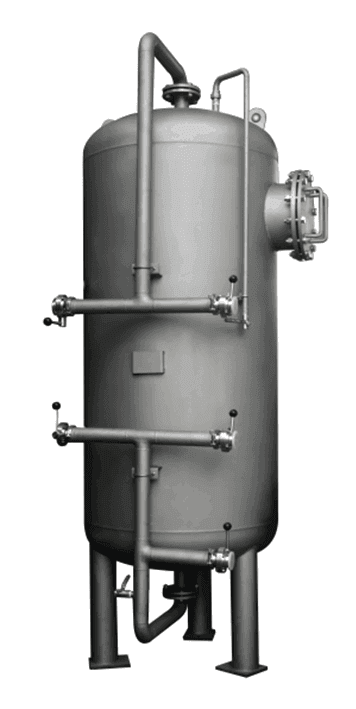

3. Active carbon filter

Dimensions: Height - 2000 mm; Diameter - 600 mm

Material: Food-grade stainless steel with mirror polishing

Components: Equipped with water sender, water collector, pressure gauge, filtration material, valves, and other essential parts.

Filter Media: Activated carbon

Application: Specially designed to eliminate water odor, residual chlorine, chlorides, and heavy metals, while reducing color and enhancing water quality.

Processing Capacity: 3 m³/h

4. Sodium ion filter

Dimensions: Height - 2000 mm; Diameter - 600 mm

Material: High-quality SUS304 stainless steel

Components: Includes water sender, water collector, pressure gauge, valve materials, acid exchange resin, dissolve measurement system, and valves.

Filter Media: Acid exchange resin

Application: Primarily designed to remove calcium and magnesium ions from water.

Flow Capacity: 3 m³/h

5. Precision filter

Dimensions: Height - 1400 mm; Diameter - 320 mm

Treatment Capacity: 3 m³/h

Filtration Precision: 5 μm

Material: Food-grade SUS304 stainless steel

Application: Specifically designed to remove fine impurities, ensuring enhanced water clarity and quality.

6. 1st grade Reverse Osmosis

Usage: This device is designed to eliminate germs, harmful inorganic and organic ions, heavy metals, and salts. It also restructures water, making it an ideal solution for producing high-standard pure drinking water.

Main Design Data:

First-Stage RO Capacity: ≥ 3 m³/h (at 25ºC)

Recovery Rate: 65-70%

7. Ozone generator

Applications: Ideal for use with tap water, mineral water, purified water, and beverage water.

Specifications:

Working Pressure: ≤ 0.08 MPa

Ozone Concentration: 20 mg/L

Ozone Capacity: 20 g/h

Usage: This product utilizes ultraviolet (UV) rays with a wavelength of 253.7-275 nm for sterilization. By generating specialized UV rays using an advanced UV generator, the system ensures thorough contact between water and UV rays. This high-tech process effectively eliminates most pathogens, including bacteria, viruses, microorganisms, and parasites.

Industry Applications: Widely used in the food and beverage industry due to its advanced sterilization capabilities and reliability.

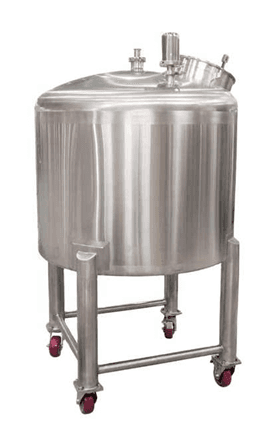

8. Water storage tank

Purpose: Designed for water storage.

Capacity: 2 tons.

Material: High-quality SUS304 stainless steel.

2000lph carbonated beverage preparation system

1. Water cooling chiller

Technical Parameters:

Nominal Cooling Capacity (at 15℃): 74,992 kcal/h (78.3 kW)

Input Power: 31.3 kW

Temperature Control Range: 0℃ to 25℃

Compressor: Hermetic scroll, 11.25 kW × 2

Cooling Airflow: 42,000 m³/h

Cooling Blower: 0.75 kW × 4

Water Pump: 4 kW

2. 500L Sugar melting tank

Usage: The sugar melting pot is designed for melting sugar into syrup through heating and stirring, ensuring it meets the required process standards. It is widely used in the production of fruit juice and carbonated beverages.

Main Parameters:

Capacity: 500 kg per cycle

Diameter: 850 mm

Height: 1700 mm

Framework Material: Food-grade SUS304 stainless steel

3. Syrup filter

Usage: The syrup filter is designed to remove impurities and dregs from the syrup produced by the sugar melting pot, ensuring the syrup becomes clear and pure. It is an essential piece of equipment in fruit juice production.

Main Parameters:

Capacity: 500 kg per cycle

Diameter: 200 mm

Height: 1000 mm

Framework Material: Food-grade SUS304 stainless steel

4. Mixing tank

Usage: The mixing tank is designed for blending water, fruit juice concentrate, and syrup through stirring to achieve a uniform mixture.

Main Parameters:

Capacity: 1000 kg per cycle

Diameter: 1000 mm

Height: 1500 mm

Framework Material: Food-grade SUS304 stainless steel

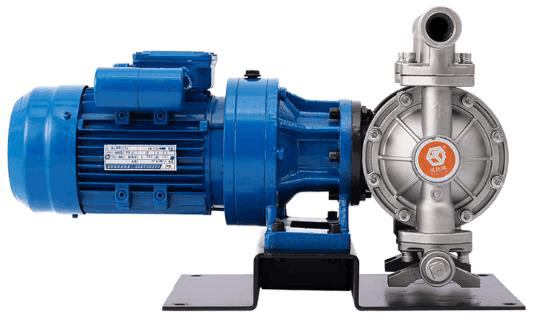

5. Pump

Pump Specifications:

Material: High-quality SUS304 stainless steel

Power: 2.2 kW

6. CO2 Purifier

Specifications:

Material: SUS304 stainless steel

Working Pressure: ≤ 0.7 MPa

Purification Precision: 99.99%

Filter Material: Potassium Permanganate & Foam

7. Drinks CO2 mixing machine

Description:

This machine is primarily used for carbonating and mixing carbonated beverages such as lemonade, cola, juice, and other carbonated drinks. It is a key piece of equipment in beverage production lines, particularly for producing medium to high-quality drinks.

Technical Parameters:

Production Capacity: 2000 kg/h

Syrup to Water Ratio Range: 1:3 - 1:10

Gas Content: CO2:H2O > 2.6

Mixing Precision: ≤ 2%

Inlet Temperature of Chilled Water: 0 ~ 5℃

Inlet Pressure of Chilled Water: 0.01 MPa ~ 0.08 MPa

Inlet Temperature of Syrup: 2 ~ 8℃

Inlet Pressure of Syrup: 0.01 MPa ~ 0.08 MPa

Inlet Pressure of CO2: 0.7 MPa ~ 0.8 MPa

Purity of Carbon Dioxide: > 99.9%

Working Pressure of Water Storage Pot and Syrup Pot: 0.05 MPa ~ 0.09 MPa

Working Pressure of Storage Pot: 0.2 MPa ~ 0.5 MPa

Power: 5 kW

Weight: 2500 kg

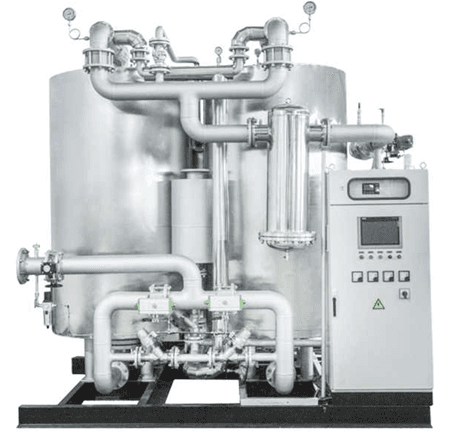

8. CIP Cleaning system

Applicable Production Line: 2 tons/hr soda or juice production line.

CIP System Description:

The CIP (Clean-in-Place) system is designed to perform washing operations on the filling machine. The washing process is fully automated, and all parameters such as washing time, pH value, washing temperature, and sequence can be pre-established on the operating touchscreen.

Operation Process:

When cleaning is needed, the operator selects the equipment to be cleaned on the touchscreen, chooses the pre-set cleaning order, and starts the system.

The CIP system will automatically complete the washing process in the pre-established sequence.

The system can also be set to call back automatically for specific phases, including acid, alkali, and water wash cycles.

Features include automatic water replenishment, pH replenishment, and temperature adjustment, with real-time displays of temperature, consistency, liquid level, and flow status, as well as acoustic and optical alarms.

Control Modes:

The system supports both automatic and manual operation modes, with all parameters adjustable via the touchscreen.

Manual operation and parameter adjustments are password-protected for security.

5000cph/250ml~500ml cans carbonated drink filling and seaming machine

1.Empty cans feeding table

Usage: This table is designed for workers to load empty cans onto the conveyor line for further processing.

Material: Food-grade SUS304 stainless steel

2. Cans washing machine, 1.5M

Usage: This machine is designed for rinsing cans before the filling process.

Overall Size: 1500 × 500 × 1500 mm

Weight: 300 kg

Material: SUS304 stainless steel

Power: 0.75 kW

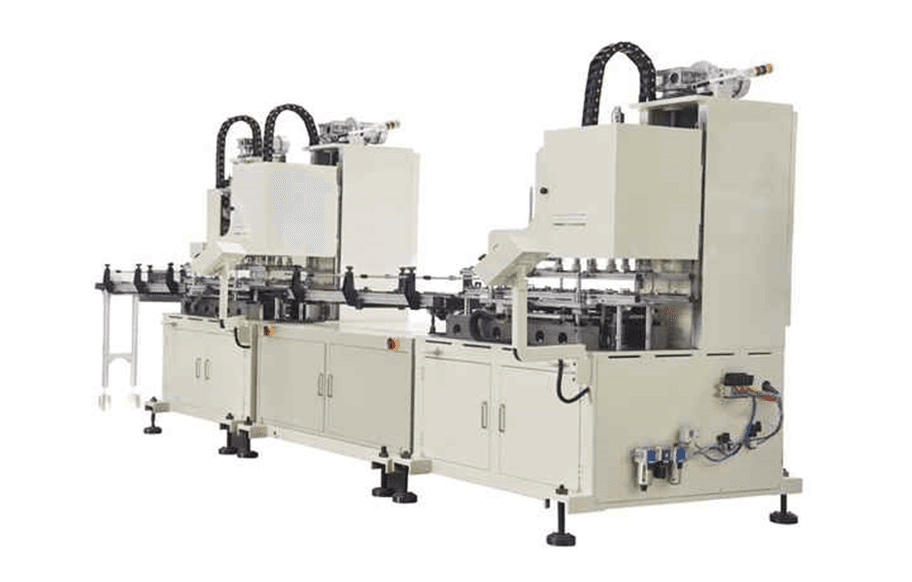

3. Carbonated drink cans filling

and seaming machine

Usage:

This machine integrates advanced filling and capping technologies introduced from abroad, offering both high performance and structure at an international level. It combines mechanical, electrical, and pneumatic controls for efficient operation. The auto liquid level control system ensures a stable filling process. The rotary-type capping system uses row-rolling to ensure one cap per can, and the system automatically stops if there are no cans or if cans are crushed. This highly automated machine is suitable for all types of pull-tab cans.

Main Parameters:

Capacity: 6000 cans per hour (330-500 ml)

Can Specifications: Φ65 mm, 122 mm height

Filling Positions: 12 positions

Sealing Positions: 4 positions

Main Power: 4.5 kW

Machine Weight: 3000 kg

4.Cans turner

Usage:

This machine is designed for turning cans after they have been rinsed, and before or after the date printing process.

Material: Plastic

Size: Adjustable to accommodate various can sizes

Packing Machines

Cans warming machine

Machine Description:

The machine body and pipeline are constructed from AISI304 stainless steel, featuring a movable top cover, front and rear windows, hand holes, and manholes for easy access. A window on one side of the wall panel allows for observation, maintenance, and cleaning. It is equipped with an insulated water tank, where the water temperature is fully automated and displayed. The nozzle uses advanced fog spray technology, ensuring uniform water distribution, high volume, and wide coverage, which supports gentle and even cooling of the treated material.

Main Technical Parameters:

Production Capacity: 6000 cans per hour (250-500 ml)

Inlet Temperature: Approximately 5℃

Outlet Temperature: Approximately 25-30℃

Rated Treatment Time: 12 ~ 15 minutes

Water Pump Power: 3 kW × 2

Overall Dimensions: 6000 × 1200 × 1800 mm

Weight: Approximately 700 kg

2. Blowing dryer

Usage:

The blowing dryer is used to remove water from bottles after the filling process. It uses clean air from a specialized blower to evenly dry the bottles.

Main Parameters:

Capacity: 6000 cans per hour

Power Consumption: 4 kW

Overall Dimensions (L × W × H): 1500 mm × 500 mm × 700 mm

Framework Material: Food-grade SUS304 stainless steel

3. Automatic inkjet printer

Height of Character: 100 type spout (20mm)

Character Types: ASCII code4) Spraying Speed: 0.5 meter/minutes~60meter/minutes (Max capacity for bottles: 10000 bottles per hour)

Interface: RS-232C

Memory Info: 80 documents

Software Function: the character is adjustable, the printing can be delayed, the width of the character, the direction of the printing, the reversion of the character, enlargement of the character,cleanout automatically .etc.

Operating environment: 38F~122F

Printing Ink: Diversified spraying ink (water craft, oil craft)

Printing Material: Osmosis and non-osmosis

Spraying Distance: 5-30mm

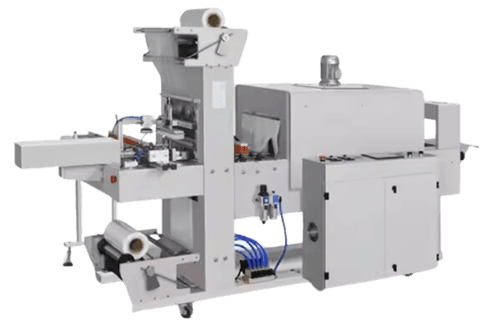

4. Automatic shrinking packing machine

Technical Specifications:

Overall Size of the Equipment: L 5050 × W 3300 × H 2100 mm

Max Package Size: L 600 × W 400 × H 350 mm

Shrink Film Material: PE, PVC, POF

Shrink Film Thickness: 0.03 - 0.15 mm

Maximum Temperature of Heating Shrinking Pot: 160 - 260°C (adjustable)

Max Production Capacity: 8 - 15 bags per minute

Equipment Power: 20 kW

Actual Power Consumption: 15 kW/h

Power Supply Requirement: 380/220V (customized)

Equipment Weight: 1.2 tons

Fan Specifications:

1.1 kW, 2 sets, 380V

65W, 4 sets, 380V